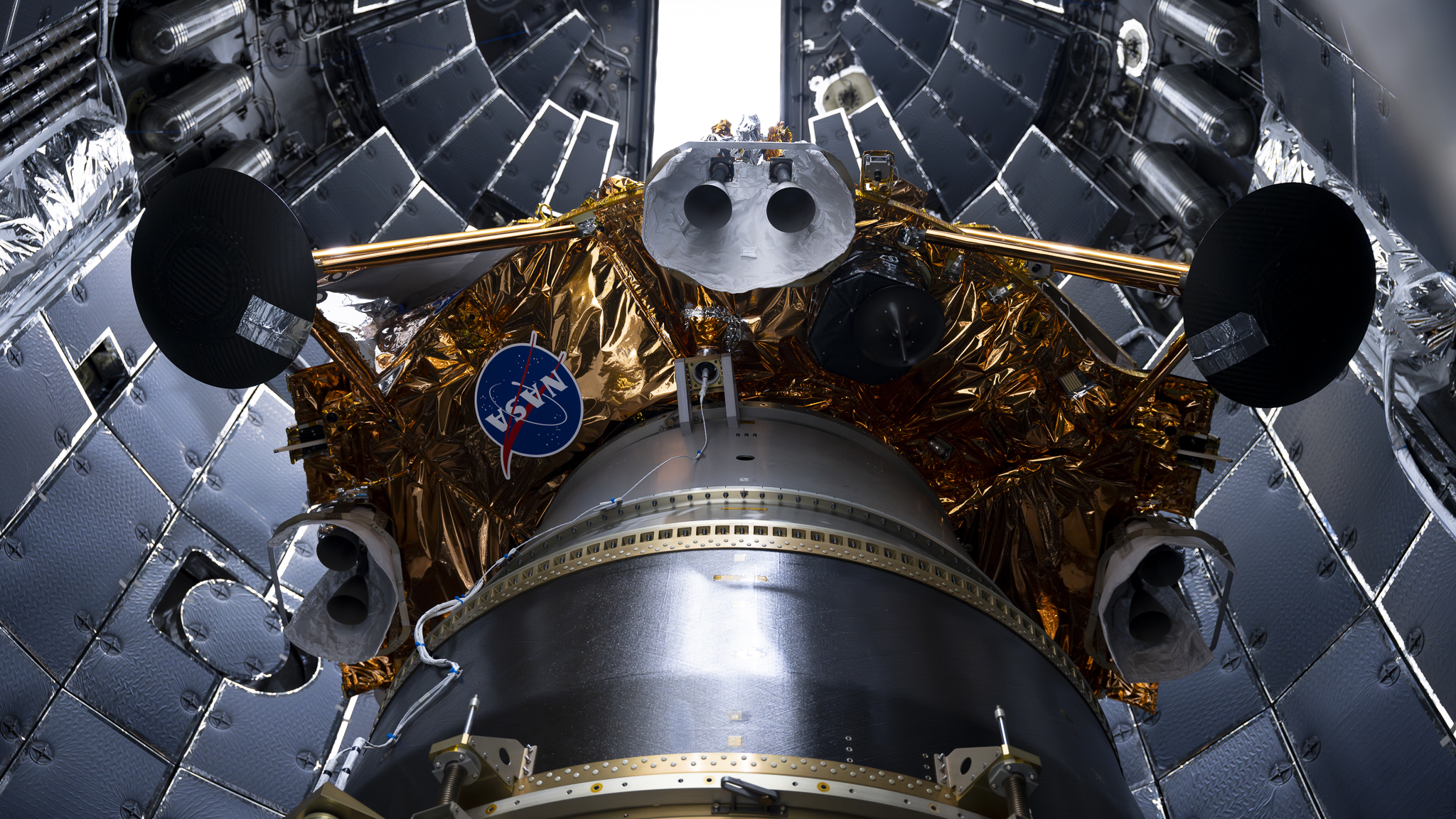

How to Fly NASA’s Orion Spacecraft

On NASA’s Artemis II test flight, the first crewed mission under the agency’s Artemis campaign, astronauts will take the controls of the Orion spacecraft and periodically fly it manually during the flight around the Moon and back. The mission provides the first opportunity to ensure the spacecraft operates as designed with humans aboard, ahead of future Artemis missions to the Moon’s surface.

The first key piloting test, called the proximity operations demonstration, will take place after the four crew members — NASA’s Reid Wiseman, Victor Glover, and Christina Koch, and CSA (Canadian Space Agency) astronaut Jeremy Hansen — are safely in space, about three hours into the mission. To evaluate the spacecraft’s manual handling qualities, the crew will pilot Orion to approach and back away from the detached upper stage of the SLS (Space Launch System) rocket.

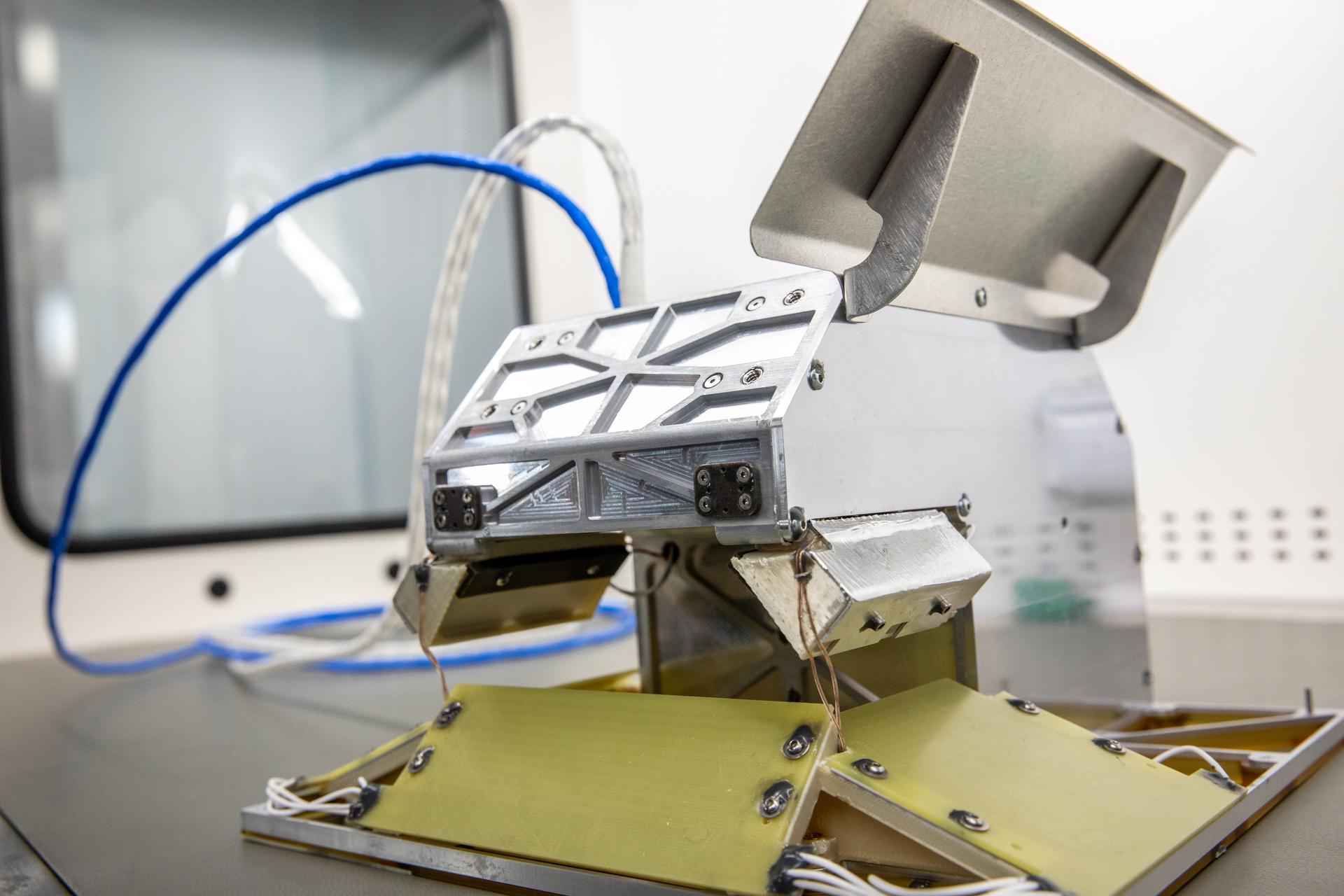

Crew members participating in the demonstration will use two different controllers, called rotational and translational hand controllers, to steer the spacecraft. Three display screens provide the astronauts with data, and another device, called the cursor control device, allows the crew to interact with the displays.

“On Artemis II, most of the time the spacecraft will fly autonomously, but having humans aboard is a chance to help with future mission success,” said Reid Wiseman. “If something goes wrong, a crewmember can jump on the controls and help fix the problem. One of our big goals is to check out this spacecraft and have it completely ready for our friends on Artemis III.”

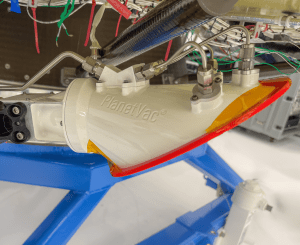

The commander and pilot seats are each equipped with a rotational hand controller (RHC), gripped in the right hand, to rotate the spacecraft. It controls Orion’s attitude, or the direction the spacecraft is pointing. If the crew wants to point Orion’s nose left, the RHC is twisted left — for nose right, they will twist the RHC right. Similarly, the RHC can control the nose to pitch up or down or roll right or left.

The translational hand controller (THC), located to the right or left of the display screens, will move Orion from one point to another. To move the spacecraft forward, the crew pushes the controller straight in — to back up, they will pull the controller out. And similarly, the controller can be pushed up or down and left or right to move in those directions.

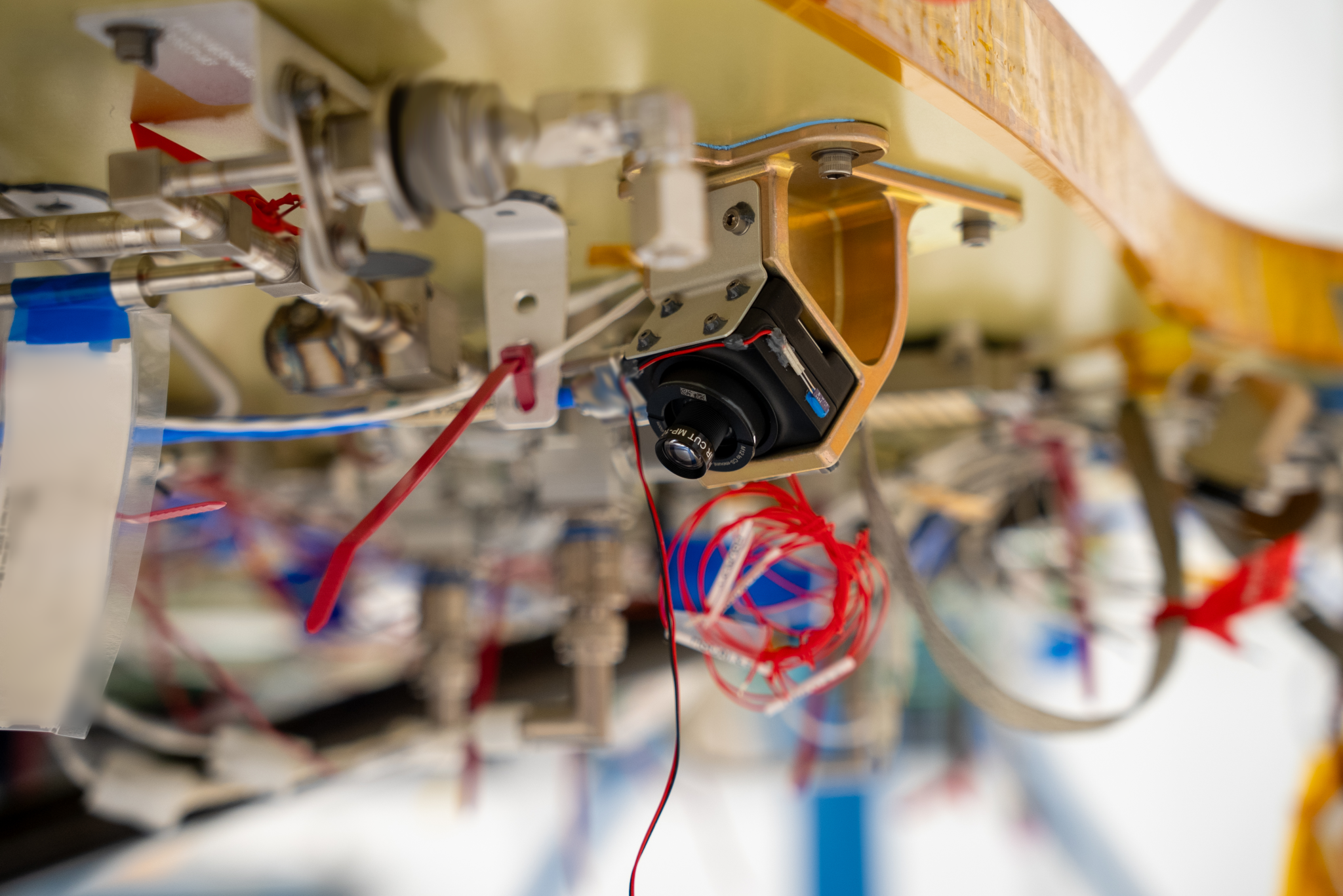

When the crew uses one of the controllers, their command is detected by Orion’s flight software, run by the spacecraft’s guidance, navigation, and control system. The flight software was designed, developed, and tested by Orion’s main contractor, Lockheed Martin.

“We’re going to perform flight test objectives on Artemis II to get data on the handling qualities of the spacecraft and how well it maneuvers,” said Jeffrey Semrau, Lockheed Martin’s manual controls flight software lead for Artemis missions. “We’ll use that information to upgrade and improve our control systems and facilitate success for future missions.”

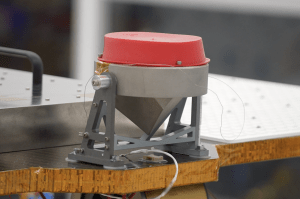

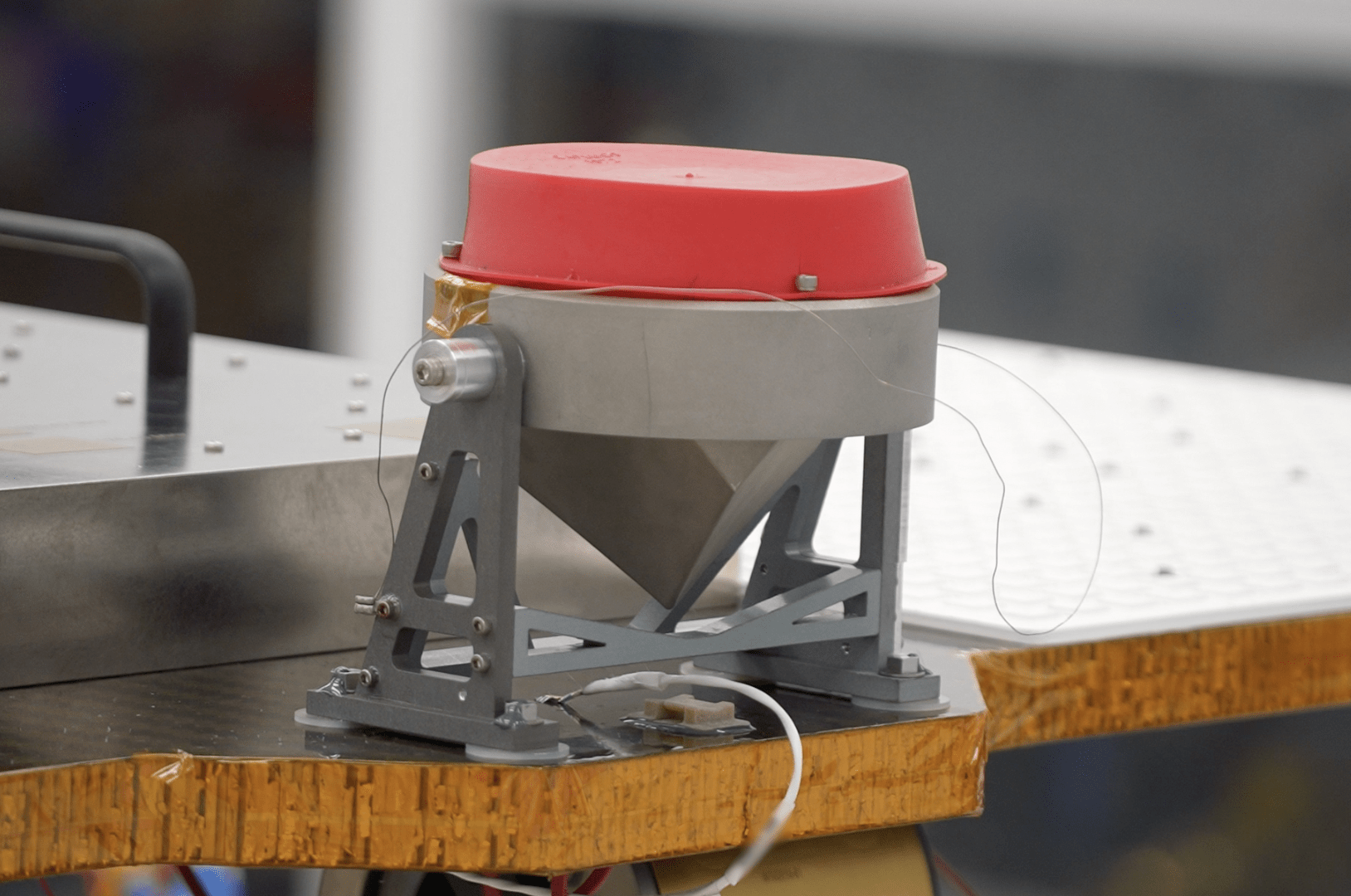

Depending on what maneuver the pilot has commanded, Orion’s software determines which of its 24 reaction control system thrusters to fire, and when. These thrusters are located on Orion’s European-built service module. They provide small amounts of thrust in any direction to steer the spacecraft and can provide torque to allow rotation control.

The cursor control device allows the crew to interact with the three display screens that show spacecraft data and information. This device allows the crew to interact with Orion even under the stresses of launch or entry when gravitational forces can prevent them from physically reaching the screens.

Next to Orion’s displays, the spacecraft also has a series of switches, toggles, and dials on the switch interface panel. Along with switches the crew will use during normal mission operations, there is also a backup set of switches they can use to fly Orion if a display or hand controller fails.

“This flight test will simulate the flying that we would do if we were docking to another spacecraft like our lander or to Gateway, our lunar space station,” said Victor Glover. “We’re going to make sure that the vehicle flies the way that our simulators approximate. And we’re going to make sure that it’s ready for the more complicated missions ahead.”

The approximately 10-day Artemis II flight will test NASA’s foundational human deep space exploration capabilities, the SLS rocket, Orion spacecraft, and supporting ground systems, for the first time with astronauts and will pave the way for lunar surface missions.