Winners Announced in NASA’s 2025 Gateways to Blue Skies Competition

3 min read

Preparations for Next Moonwalk Simulations Underway (and Underwater)

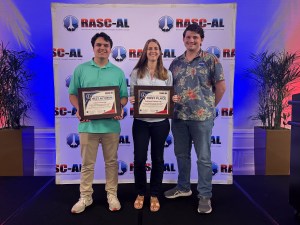

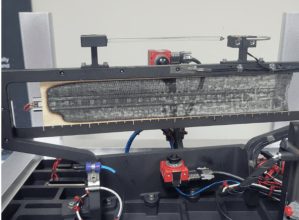

A team from South Dakota State University, with their project titled “Soil Testing and Plant Leaf Extraction Drone” took first place at the 2025 NASA Gateways to Blue Skies Competition, which challenged student teams to research aviation solutions to support U.S. agriculture.

The winning project proposed a drone-based soil and tissue sampling process that would automate a typically labor-intensive farming task. The South Dakota State team competed among eight finalists at the 2025 Blue Skies Forum May 20-21 in Palmdale, California, near NASA’s Armstrong Flight Research Center. Subject matter experts from NASA and industry served as judges.

“This competition challenges students to think creatively, explore new possibilities, and confront the emerging issues and opportunity spaces solvable through aviation platforms,” said Steven Holz, assistant project manager for University Innovation with NASA’s Aeronautics Research Mission Directorate and Blue Skies judge and co-chair. “They bring imaginative ideas, interesting insights, and an impressive level of dedication. It’s always an honor to work with the next generation of innovators participating in our competition.”

This competition challenges students to think creatively, explore new possibilities, and confront the emerging issues and opportunity spaces solvable through aviation platforms

Steven holz

Assistant Project Manager for University Innovation

The winning team members were awarded an opportunity to intern during the 2025-26 academic year at any of four aeronautics-focused NASA centers — Langley Research Center in Hampton, Virginia, Glenn Research Center in Cleveland, Ames Research Center in California’s Silicon Valley, or Armstrong Flight Research Center in Edwards, California.

“It’s been super-rewarding for our team to see how far we’ve come, especially with all these other amazing projects that we were competing against,” said Nathan Kuehl, team lead at South Dakota State University. “It wouldn’t have been possible without our graduate advisor, Allea Klauenberg, and advisor, Todd Lechter. We want to thank everybody that made this experience possible.”

Other awards included:

- Second Place — University of Tulsa, CattleLog Cattle Management System

- Best Technical Paper — Boston University, PLAANT: Precision Land Analysis and Aerial Nitrogen Treatment

Sponsored by NASA’s Aeronautics Research Mission Directorate, this year’s competition asked teams of university students to research new or improved aviation solutions to support agriculture that could be applied by 2035 or sooner. The goal of the competition, titled AgAir: Aviation Solutions for Agriculture, was to enhance production, efficiency, sustainability, and resilience to extreme weather.

At the forum, finalist teams presented concepts of aviation systems that could help the agriculture industry.Students had the opportunity to meet with NASA and industry experts, tour NASA Armstrong, and gain insight into the agency’s aviation mission.

U.S. agriculture provides food, fuel, and fiber to the nation and the world. However, the industry faces significant challenges. NASA Aeronautics is committed to supporting commercial, industrial, and governmental partners in advancing aviation systems to modernize agricultural capabilities.

The Gateways to Blue Skies competition is sponsored by NASA’s Aeronautics Research Mission Directorate’s University Innovation Project and is managed by the National Institute of Aerospace.

The National Institute of Aerospace has made available a livestream of the competition, as well as information about the finalists and their projects, and details about the 2025 competition.